False Ceiling Hardware

Product Details:

- Coating Zinc Coated

- Pattern Perforated or Plain

- Thickness 0.4 mm to 1.2 mm

- Material Galvanized Iron

- Product Type False Ceiling Hardware

- Ceiling Suitable for Gypsum and Grid Ceilings

- Color Silver

- Click to View more

False Ceiling Hardware Price And Quantity

- 4 INR/Piece

- 120 Piece

False Ceiling Hardware Product Specifications

- Suspended Ceilings, modular ceiling systems, Commercial and Residential spaces

- Smooth

- Galvanized

- Corrosion Resistant, High Strength, Easy Installation

- Customizable, Standard Lengths: 2.4 m, 3 m

- Suitable for Gypsum and Grid Ceilings

- Silver

- 0.4 mm to 1.2 mm

- Perforated or Plain

- Zinc Coated

- Galvanized Iron

- False Ceiling Hardware

False Ceiling Hardware Trade Information

- 15000 Piece Per Month

- 1 Week

Product Description

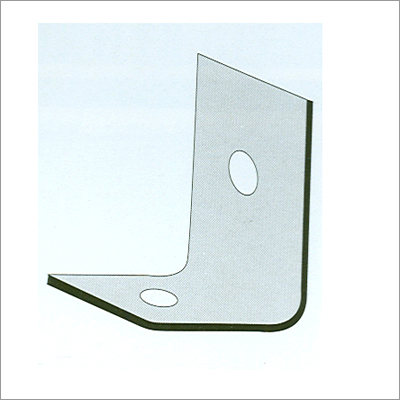

False Ceiling Hardware

Owing to our consistent performance in the hardware industry, we have been able to carve a niche in the market and reckoned as foremost manufacturers of False Ceiling Hardware. Our wide range of ceiling hardware is widely used to hold the ceiling angle, level clip, MS flat for the suspensions of framework from the structural soffit. This False Ceiling Hardware is well accepted in the market for its features like rugged design, dimensional accuracy and optimum quality.

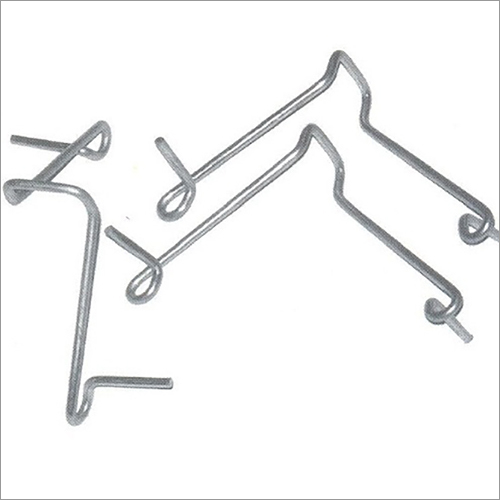

Further Details:

The connecting clips that we are offering are available in varied diameters ranging from 2.5 mm and 2.64 mm dia. In these, a spring steel wire is provided to suit and hold the ceiling section & intermediate channel together to form a regular frame.

Engineered for Strength and Durability

Manufactured using galvanized iron with thicknesses ranging from 0.4 mm to 1.2 mm, these false ceiling hardware components provide excellent load-bearing capacity. Their high-strength properties make them reliable for both residential and commercial projects, ensuring stability and long-term performance.

Versatile Application and Customizable Options

Designed for compatibility with various ceiling types, including gypsum and grid systems, this hardware offers smooth finishes in both perforated and plain patterns. Available in silver, with zinc-coated protection, each component can be customized to your size requirements, making them ideal for modular ceiling solutions.

FAQs of False Ceiling Hardware:

Q: How does galvanized iron improve the performance of false ceiling hardware?

A: Galvanized iron is coated with a layer of zinc, which protects the hardware from corrosion and extends its lifespan. This makes it particularly suitable for suspended ceilings in both commercial and residential spaces, where durability and low maintenance are essential.Q: What are the key benefits of using this hardware for suspended ceilings?

A: The key benefits include high strength, corrosion resistance, and easy installation. The smooth, zinc-coated finish also ensures that the hardware maintains its appearance and structural integrity over time, while customizable sizes and patterns provide flexibility for various ceiling designs.Q: When should I choose perforated versus plain patterns for ceiling hardware?

A: Perforated patterns are often selected to enhance acoustic performance and ventilation, which can be advantageous in offices or commercial settings. Plain hardware is typically used where a solid, uniform appearance is desired, such as in residential spaces or decorative applications.Q: Where can this false ceiling hardware be installed?

A: This hardware is suitable for a wide range of locations, including residential and commercial spaces, thanks to its strength and corrosion resistance. It is designed to support gypsum and grid ceilings, making it ideal for offices, retail shops, homes, and other modular ceiling systems.Q: What is the process for installing galvanized iron ceiling hardware?

A: Installation is designed to be user-friendly. After selecting the appropriate sizes and patterns, the hardware is positioned to support ceiling panels. Its smooth surface and lightweight construction facilitate efficient setup, saving time and effort on-site.Q: How does the zinc coating provide added value to ceiling hardware?

A: The zinc coating acts as a protective barrier, shielding the hardware from moisture and environmental factors that cause rust. This prolongs the life of the ceiling system, reduces maintenance needs, and keeps the appearance clean over time.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

Call Me Free

Call Me Free